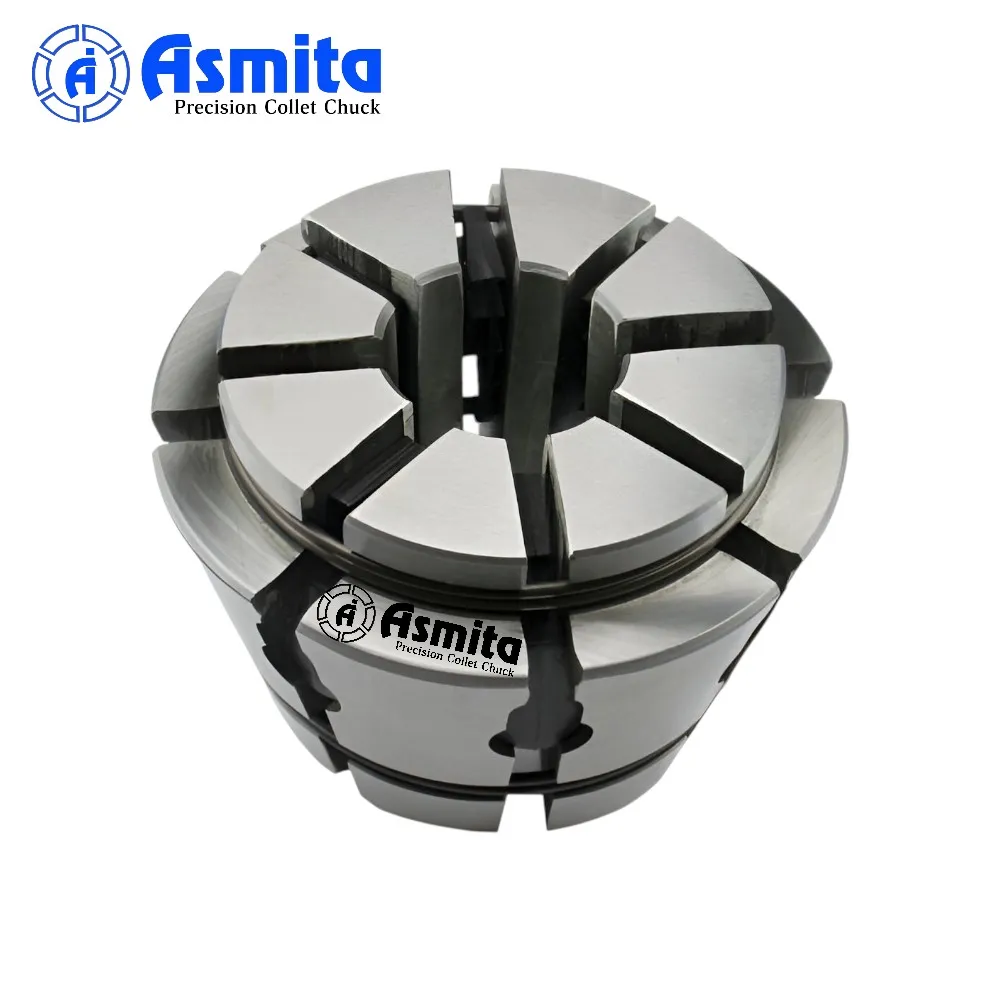

An Expanding Nut Adaptor is a compact internal clamping device used to hold components securely from the inside diameter (ID) by radial expansion.

When tightened, the adaptor expands uniformly inside the bore, providing strong, concentric, and distortion-free holding—ideal for machining, grinding, inspection, and balancing operations.

It is especially effective for thin-wall, short-length, or small-bore components where external clamping is not feasible.

Applications

Expanding Nut Adaptors are commonly used in:

- CNC turning & milling

- OD turning, facing & boring

- Grinding & inspection setups

- Bushes, sleeves & rings

- Thin-wall & precision components

- Toolroom and batch production work

Key Features

- ✔ Uniform 360° internal expansion

- ✔ High concentricity & repeatability

- ✔ Distortion-free clamping for thin walls

- ✔ Quick tightening and release

- ✔ Compact design for short components

- ✔ Hardened & precision-ground expanding parts

- ✔ Suitable for high-accuracy operations

- ✔ Custom bore sizes and expansion ranges

Working Principle

The adaptor consists of an expanding sleeve/segments actuated by a tapered screw or nut.

As the nut is tightened, axial force converts into radial expansion, gripping the bore evenly without marking or ovality.

Technical Specifications

- Clamping Type: Internal (ID expanding)

- Actuation: Mechanical (nut-driven)

- Material: Alloy Steel / Tool Steel

- Hardness: 55–60 HRC (working surfaces)

- Accuracy: ≤ 0.01 mm TIR

- Expansion Range: Typically 0.2–0.6 mm (customizable)

- Mounting: Straight shank / threaded / custom interface

- Customization: As per drawing or sample

Advantages

- Eliminates external clamping marks

- Ensures true concentric machining

- Faster setup than mandrels or fixtures

- Cost-effective for small batches

- Ideal for precision and repeat work