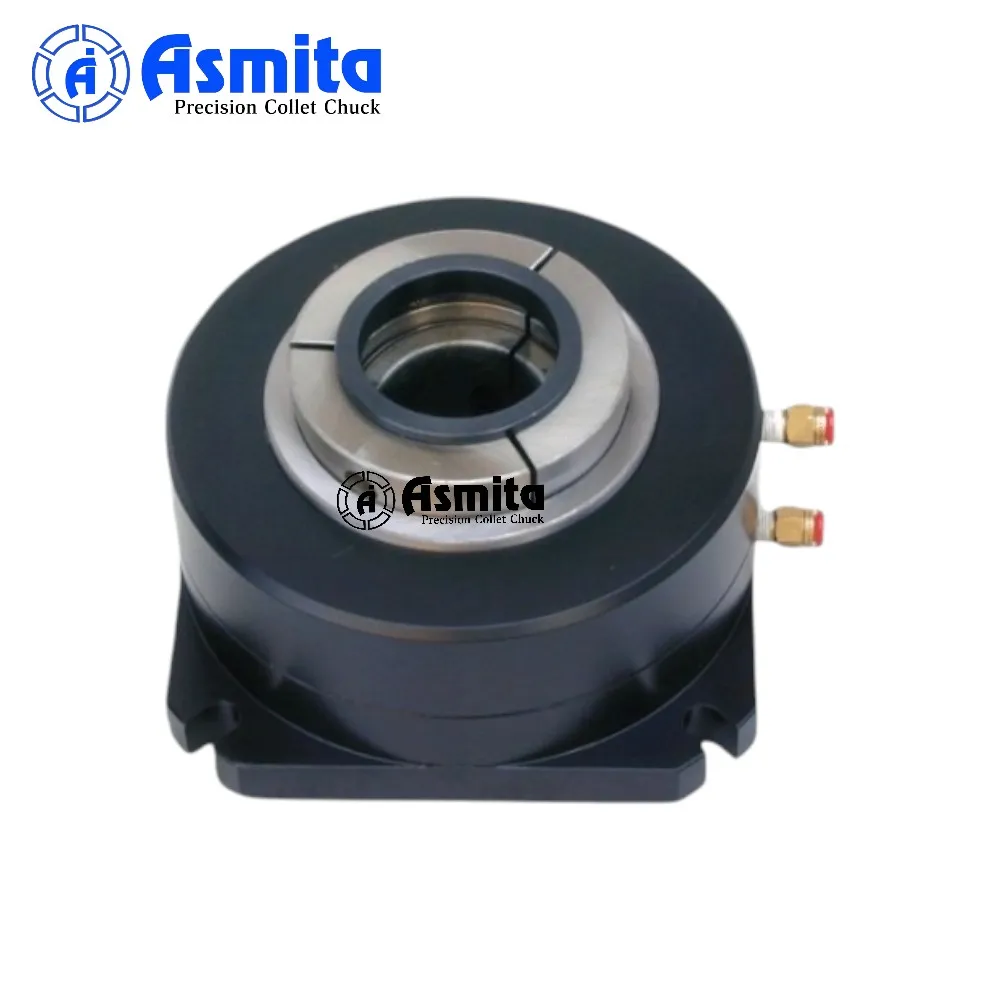

Hydraulic Stationary Jaw Type Chuck is a non-rotating, hydraulically actuated workholding system engineered to deliver very high and consistent clamping force with dead-length accuracy (no axial movement of the job during clamping). Because the chuck body remains stationary, it offers maximum rigidity, safety, and repeatability, making it ideal for CNC stationary operations, SPMs, transfer lines, and automated production cells.

Compared to pneumatic stationary chucks, the hydraulic version provides higher grip force and better stability for heavy machining and hard materials.

🔑 Key Features

- 💧 Hydraulic Actuation (High & Constant Clamping Force)

- 🧱 Stationary / Non-Rotating Body

- 🎯 Dead-Length Clamping (Zero Axial Shift)

- 🔩 Jaw Type Clamping – 3-Jaw Standard (4-Jaw Optional)

- 🛠️ Hardened & Ground Alloy Steel Construction

- 🔄 Fast Clamp–Unclamp (Automation Ready)

- 🔧 Long Service Life, Low Maintenance

📐 Dimension Reference – Hydraulic Stationary Jaw Type

🔩 Dimension Legend

|

Symbol

|

Description

|

|

A

|

Chuck outer diameter

|

|

B

|

Mounting face diameter

|

|

C

|

Jaw clamping capacity

|

|

D

|

Front face thickness

|

|

E

|

Chuck body length

|

|

F

|

Jaw stroke

|

|

G

|

Rear pilot / register

|

|

H

|

Overall length

|

|

I (PCD)

|

Pitch circle diameter (mounting)

|

|

J

|

Mounting bolt size

|

✔ Front & sectional drawings (PDF/DWG) provided

✔ Custom PCD, pilot diameter, jaw stroke & jaw type available

📊 Typical Capacity (Reference)

|

Model

|

Jaw Capacity

|

Operating Pressure

|

Mounting

|

|

HSJ-25

|

up to 25 mm

|

20–35 bar

|

Flange / Backplate

|

|

HSJ-42

|

up to 42 mm

|

20–35 bar

|

Flange / Backplate

|

|

HSJ-60

|

up to 60 mm

|

20–35 bar

|

Flange / Backplate

|

|

HSJ-80

|

up to 80 mm

|

20–35 bar

|

Flange / Backplate

|

(Exact dimensions depend on jaw type and application.)

⚙️ Operating Parameters

- Hydraulic pressure: 20–35 bar (typical)

- Clamping type: Jaw type (stationary)

- Dead-length action: Yes

- Repeatability: ≤ 0.01 mm (≤ 0.005 mm optional)

- Control: Hydraulic power pack + solenoid / PLC / CNC

- Sealing: Chip & coolant resistant

🏭 Applications

- CNC stationary turning & facing

- Heavy machining on SPMs

- Transfer lines & automated fixtures

- Automotive & engineering components

- Parts requiring high grip & length accuracy

⭐ Why Choose Hydraulic Stationary Jaw Type Chuck?

✔ Much higher grip than pneumatic stationary chucks

✔ Zero axial movement for consistent part length

✔ Excellent rigidity & machining stability

✔ Ideal for heavy cuts & hard materials

✔ Perfect for automation & mass production